.

The Laterite Story

Of the various soil types that occur in the tropics and sub-tropics, laterites are of special interest in conjunction with building construction. These are highly weathered soils, which contain large, though extremely variable, proportions of iron and aluminium oxides, as well as quartz and other minerals. They are found abundantly in the tropics and sub-tropics, where they generally occur just below the surface of wide grasslands or forest clearings in regions with high rainfall. The colours can vary from ochre through red, brown, violet to black, depending largely on the concentration of iron oxides.

The special characteristics of laterites, by which they differ from other soils, are:

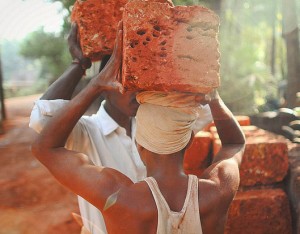

• Soft occurrences tend to harden on exposure to air, which is why blocks have traditionally (eg in India) been cut in situ, allowed to harden and then used for masonry wall construction (hence the name was derived from “later”, the latin word for “brick”).

• The darker the laterite, the harder, heavier and more resistant to moisture it is.

• Some laterites are found to have a pozzolanic reaction when mixed with lime (which can be explained by the high clay content), producing hard and durable building materials (eg stabilized blocks).

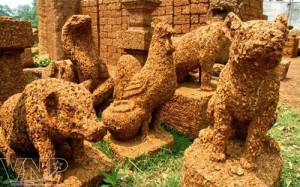

Laterite is well known in Asian countries as a building material for more than 1000 years. It was excavated from the soil and cut in form of large blocks; temples at Angkor are famous examples for this early use. At begin of the 19.century it obtained scientific interest when the English surgeon Francis Buchanan travelled along the western coast of southern India and published his manifold observations and results. He coined the term laterite when he wrote (1807): “What I have called indurated clay …is one of the most valuable materials for building. It is diffused in immense masses, without any appearance of stratification and is placed over the granite that forms the basis of Malayala. It is full of cavities and pores, and contains a very large quantity of iron in the form of yellow and red ochres. In the mass, while excluded from the air, it is so soft, that any iron instrument readily cuts it, and is dug up in square masses with a pick-axe, and immediately cut into the shape wanted with a trowel, or large knife. It very soo after becomes as hard as brick, and resists the air and water much better than any brick that I have seen in India. … The most proper English name would be laterite, from lateritis, the appellation that may be given to it in science”. (The Latin word later means brick)

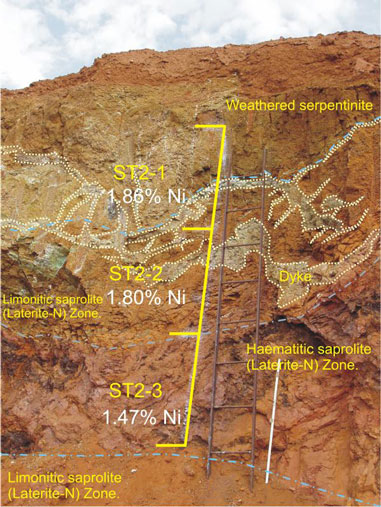

A modern laterite definition should comprise all products of intensive tropical weathering independent of their parent rocks, which strongly control the composition and the property of the weathering product. Red brown laterites on granites, granitic gneisses, clays and shales are generally hard or harden after drying, whereas laterites an basalts are commonly friable and show an intensive reddish color. Lateritization on alkaline rocks (nephelinesyenites, phonolites) often results in formation of highly aluminious laterites (bauxites) with light color. On ultramafic rocks (serpentinites etc.) forms very soft, yellow-brown Ni-bearing goethite (nickel limonite ore). The described weathering products are formed by the same fundamental weathering process and can therefore be interpreted as different members of a laterite family.

Chemical alteration

All laterites are marked by an enrichment of iron and a decrease of silica together with the highly soluble alkalis and alkaline earths. But apart of these characteristics the composition and properties of laterites can be quite different and are strongly controlled by the chemical and physical features of the parent rock. Above all the behaviour of aluminium is not uniform. In essence two principal groups can be distinguished :

– Laterites on mafic (basalt, gabbro) and on ultramafic rocks (serpentinite, peridotite, dunite). These rocks are free of quartz and show lower silica and higher iron contents.

– Laterites on acidic rocks. In this group not only granites and granitic gneisses but also many sediments as clays, shales and sandstone shall be included. These rocks contain quartz and have higher silica and lower iron contents.

The laterites formed above these rocks do not only show divergent chemical compositions but also contrasting physical properties. The very ferruginous yellowish brown laterite (nickel limonite) on serpentinite is generally soft and displays a very fine porosity, indicated by a low bulk density. In few occurences a hard cuirass has formed at the surface by dissolution and re-precipitation of iron. Also the laterites on basalts are commonly soft and friable. They are intensively red brown coloured and form relatively fertile soils. The laterites on acidic rocks behave quite differently. They frequently show a typical sequence with a pallid zone (saprolite), a mottled zone and a dark brown laterite on top which is often described. These laterites harden after drying which often allows their application as brickstones.

When moist, laterites can be easily cut with a spade into regular-sized blocks. Laterite is mined while it is below the water table, so it is wet and soft. Upon exposure to air it gradually hardens as the moisture between the flat clay particles evaporates and the larger iron salts lock into a rigid lattice structure and become resistant to atmospheric conditions. The art of quarrying laterite material into masonry is suspected to have been introduced from the Indian subcontinent.

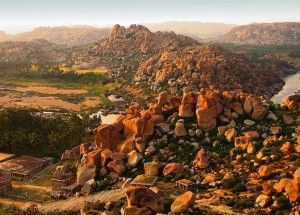

After 1000 CE Angkorian construction changed from circular or irregular earthen walls to rectangular temple enclosures of laterite, brick and stone structures. Geographic surveys show areas which have laterite stone alignments which may be foundations of temple sites that have not survived. The Khmer people constructed the Angkor monuments – which are widely distributed in Cambodia and Thailand – between the 9th and 13th centuries. The stone materials used were sandstone and laterite; brick had been used in monuments constructed in the 9th and 10th centuries. Two types of laterite can be identified; both types consist of the minerals kaolinite, quartz, hematite and goethite. Differences in the amounts of minor elements arsenic, antimony, vanadium and strontium were measured between the two laterites.

More informations

1) The laterite is either cut using a machine cutter blade or is blasted or cut using a hydraulic cutting tool seen with the heavy excavating machines. The laterite so cut instead of having it as a regular brick can be used as rubble for paving underneath foundations or used as stones for rubble masonry as what can be seen in Swaswara.

This can be used as a filler material for plum concrete where in the concrete structures are massive and heavy- retaining walls of not less than 60 cm thickness etc..

2) The compressive strength of laterite is around 120 Kg/sqcm. Taking this strength, the thickness required will be very less. However, the charcter of laterite is so that a minimum thickness of atleast 30cm will be required to avoid breaking when quarrying out.

3) Laterite extraction at site is possible, but the really hard upper layer has to be removed first to reach the soft layers, below. Then the extraction can be done with the locally available tools. Hopefully this can be arranged from the local people.

However quarrying of stones might need permissions. This can be resolved by extraction only from the site where excavation is required.

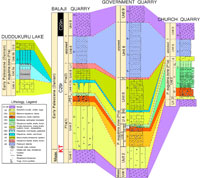

Quarry

Past…

Landscape

Magic Circle